FRP MOULDED GRATINGS

Product Details:

- Height 25, 30, 38 mm Millimeter (mm)

- Length 3.66 meter Meter (m)

- Shape Rectangle

- Product Type FRP Moulded grating

- Material FRP

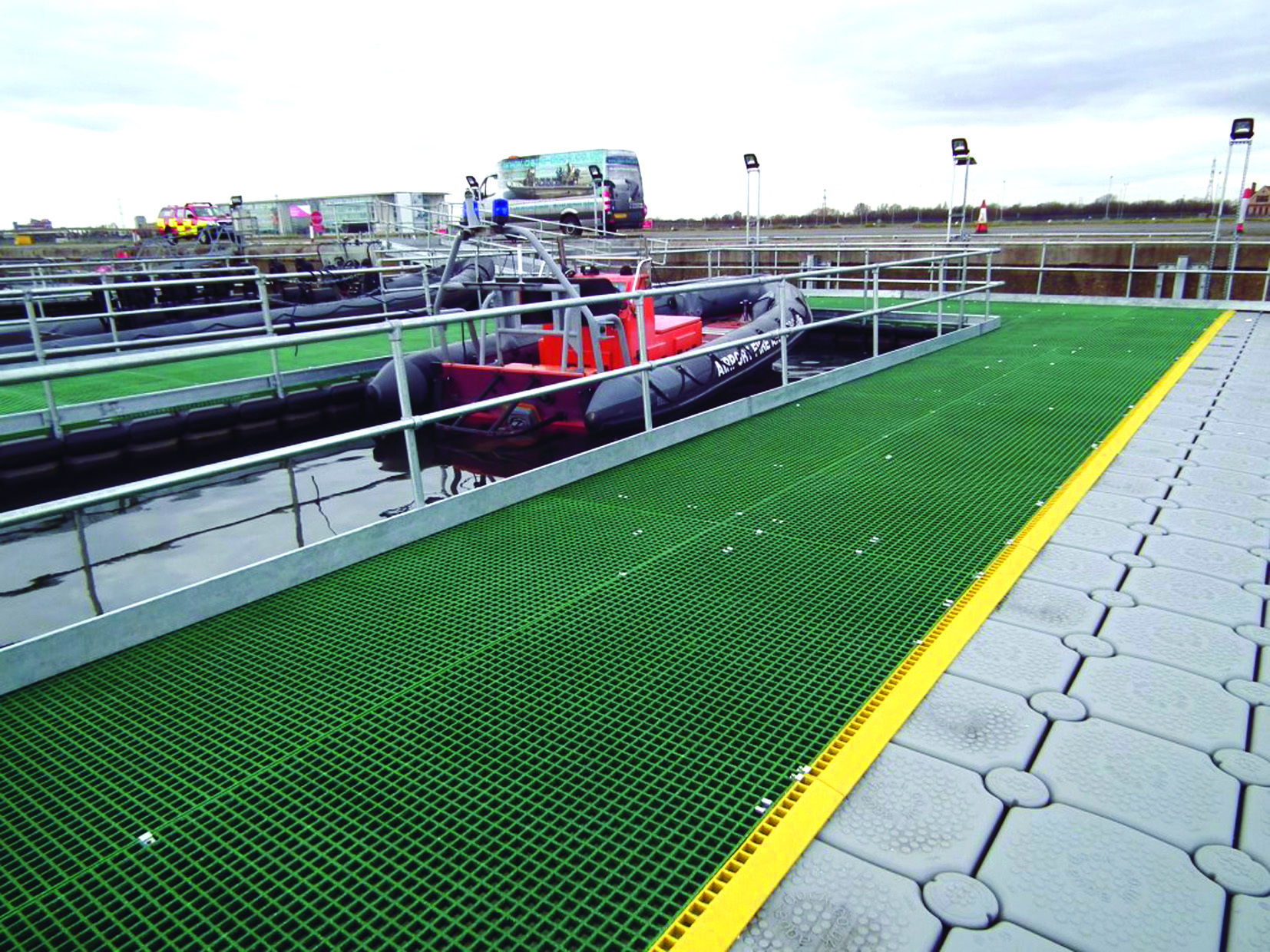

- Application Industrial Marine Mining Chemical Oil & Gas EMI / RFI Testing Pollution Control Power Plants Pulp & Paper Offshore Recreation Building Construction Metal Finishing Water / Wastewater Transportation Plating Electrical Radar

- Size 1220 x 3654 mm

- Click to view more

FRP MOULDED GRATINGS Price And Quantity

- 1750 INR/Piece

- 1750.00 - 2450.00 INR/Piece

- 1 Piece

FRP MOULDED GRATINGS Product Specifications

- Rectangle

- FRP Moulded grating

- 1220 x 3654 mm

- FRP

- 3.66 meter Meter (m)

- 25, 30, 38 mm Millimeter (mm)

- Industrial Marine Mining Chemical Oil & Gas EMI / RFI Testing Pollution Control Power Plants Pulp & Paper Offshore Recreation Building Construction Metal Finishing Water / Wastewater Transportation Plating Electrical Radar

FRP MOULDED GRATINGS Trade Information

- mundra (kutch)

- 20000 Piece Per Week

- 5 Days

- Free samples are available

- All India

Product Description

Frp Moulded Gratings

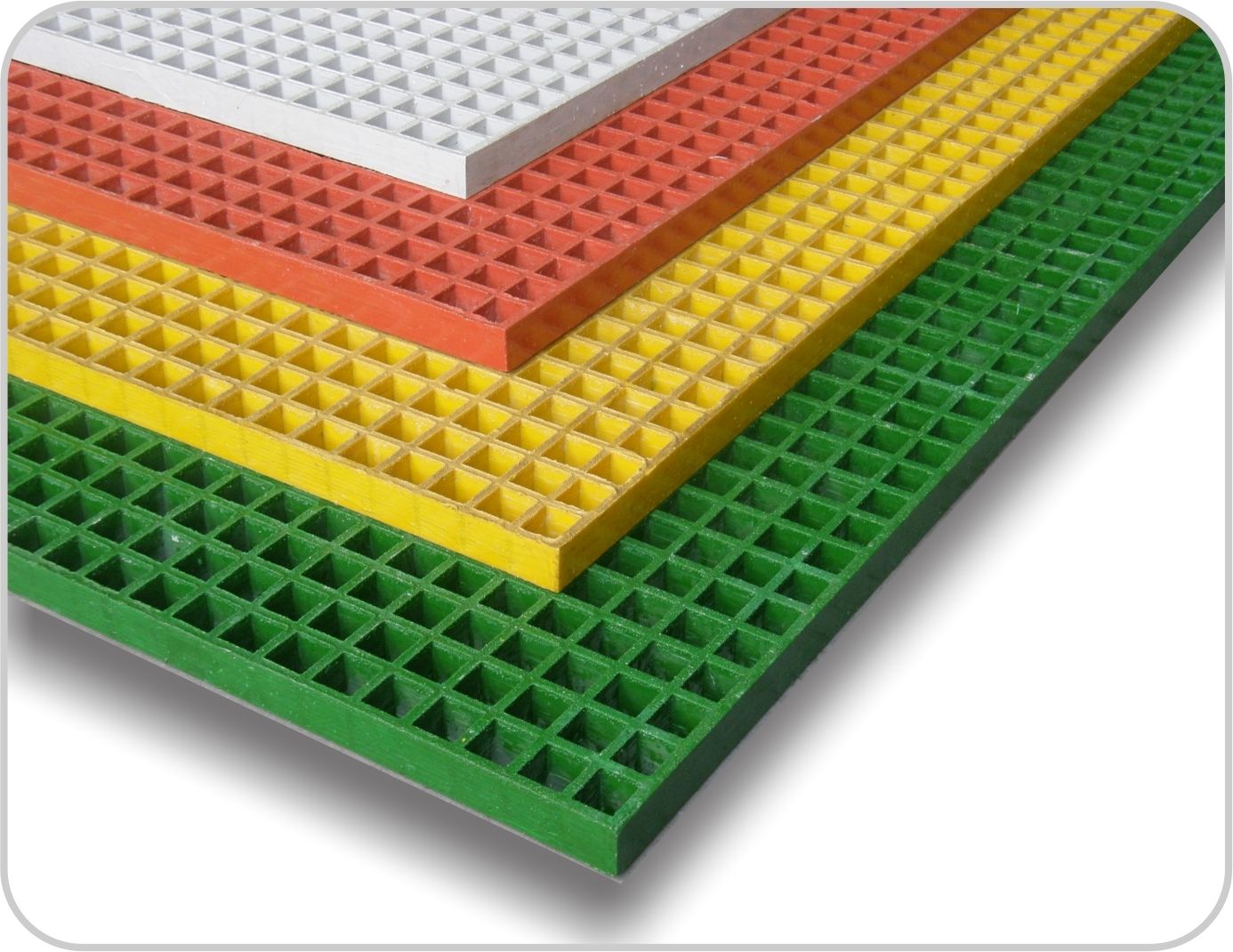

FiberTech FRP Moulded Grating Are Manufactured In An Open, Heated Mould System By Professional Skilled Workers. Continuous Glass Roving Is Laid Down In The Mould In Alternating Layers In Both Directions And Completely Soaked Out With Resin. This Continuous Process Produces An Integral Plates Which Provides Excellent Corrosion Resistance As Well As Bi-Directional Strength

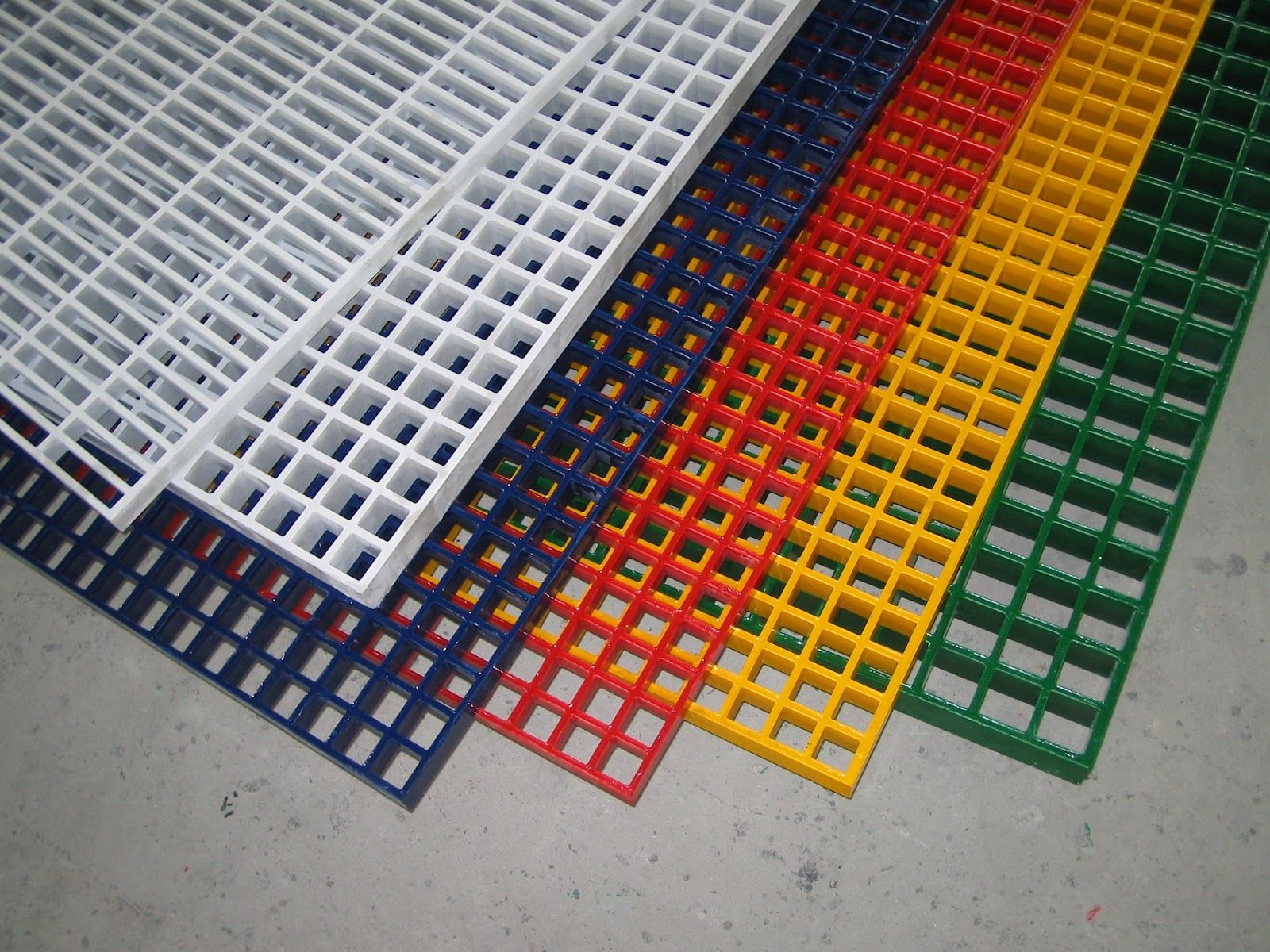

FRP Moulded Gratings Are Engineered To Provide Proven Corrosion Resistance And Reliable Service Under Extreme Conditions. The Interwoven Square Mesh Construction Provides Bi-Directional Strength Allowing For Efficient Panel Usage And Cutting To Minimise Waste. The High Resin To The Glass Ratio Provides Excellent Service Life In The Most Demanding Applications.

Assets For Fiber-Tech FRP Gratings Are : -

CORROSSION RESISTANT It Gives Resistance Against Almost All Chemicals & In Most Hostile Environments.

LIGHT WEIGHT Density Compared To Steel Is 4 Times Less.

NON CONDUCTIVE It Does Not Carry Any Electric Current.

IMPACT RESISTANCE Returns To Original Position Without Any Permanent Deflection Or Distortion. DIMENSIONAL STABILITY The Coefficient Of Thermal Expansion Of Pultruded Products Are Marginally Very Less Then Aluminum And Steel.

MAINTENANCE FREE No Rework Like Painting Or Cleaning Required.

LIFE CYCLE Long Durability Ensures Lowest In Life Cycle Cost.

EASY TO INSTALL No Welding Required While Installing.

UV RESISTANT Inbuilt UV-Resistance Gives Protection From Direct Sunlight Exposure.

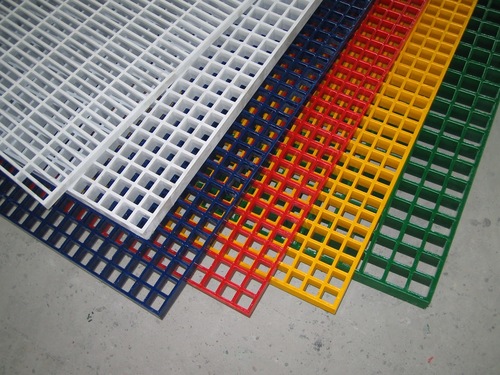

LOW INSTALLATION COST Being Light-Weight, It Can Be Installed By Anybody Easily.No Rusting No Painting Required As The Colour Is Inbuilt And Different Colour Options Are Available To Suit Your Plant Colour.

Very High Strength To Weight Ratio Which Helps In Structural Saving.

It Is Resistant To Microbial Growth.

High Impact & Fatigue Strength.

Fire Retardant.

Resistant to Chipping & Cracking.

Aesthetically Pleasing Appearance.

Anti-Skid options available.

RESIN SELECTION CHART

RESIN TYPE

GRATING TYPE

DESCRIPTION

APPLICATION

- Vinyl Ester

- Type VE

- Superior Corrosion Resistance

- Environment With High Corrosion Problems.

- Flame Resistant Vinyl Ester

- Type VE-FR

- Superior Corrosion & Flame Resistance

- Environment With High Corrosion Requiring Better Flame Resistance.

- Isophthalic Polyester

- Type IP

- Industrial Grade Corrosion Resistance

- Used In The Environments Of Normal or Less Concentration Inorganic Acid, Alkali, Etc.

- Flame resistant Isophtalic Polyester

- Type IP-FR

- Industrial Grade Corrosion & Flame Resistance

- Used In Less Concentrated Inorganic Acidic Areas Requiring better flame resistance.

- Orthophthalic Polyester

- Type OP

- Moderate Grade Corrosion Resistance

- For Use In Environment Which Requires Water & Weather-Proof Solution.

Product details

| Product Type | Grating |

| Brand | FTC |

| Shape | Square,Rectangular |

| Color | Yellow,White, Blue, Red, Yellow, Green,Silver,Black |

| Material Grade | Fiber Reinforced Polymer |

| Usage | Domestic,Agricultural,Industrial |

| Size | 1223 x 3654 |

Versatile Applications

FRP Moulded Gratings are used in industries such as marine, mining, petrochemicals, and construction. Their properties make them suitable for environments requiring corrosion resistance and durability.

Corrosion-Resistant and Durable

Made from Fiber Reinforced Polymer, these gratings provide outstanding resistance to environmental factors, ensuring longevity even under harsh conditions.

FAQs of FRP MOULDED GRATINGS:

Q: What are FRP Moulded Gratings used for?

A: FRP Moulded Gratings are utilized in industrial, marine, chemical, and construction applications, serving purposes where strong, lightweight, and corrosion-resistant materials are required.Q: How are these gratings manufactured?

A: These gratings are produced by a moulding process using Fiber Reinforced Polymer, ensuring consistent quality and structural integrity throughout the product.Q: What sizes are available for FRP Moulded Gratings?

A: Available in rectangular shapes, their dimensions are 1220 x 3654 mm, with height options of 25, 30, or 38 mm to cater to varying requirements.Q: When should I use FRP Moulded Gratings?

A: They are ideally suited when corrosion resistance, non-conductivity, and strength are needed, such as in chemical plants and wastewater facilities.Q: Where can FRP Moulded Gratings be installed?

A: These gratings can be installed in Pollution Control, Power Plants, Oil & Gas, EMI/RFI testing areas, and more.Q: What are the benefits of using FRP Moulded Gratings?

A: The key benefits include corrosion resistance, reduced maintenance costs, non-conductivity, and high strength-to-weight ratio, making them cost-effective and safe.Q: What industries commonly use FRP Moulded Gratings?

A: Industries like marine, industrial, construction, pollution control, and radar station setups often employ these gratings due to their specialized properties.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'FRP Gratings' category

1st FLOOR, GANDHI CHAMBERS,

GONDAL ROAD,

RAJKOT - 360 002 (GUJARAT) INDIA.