Showroom

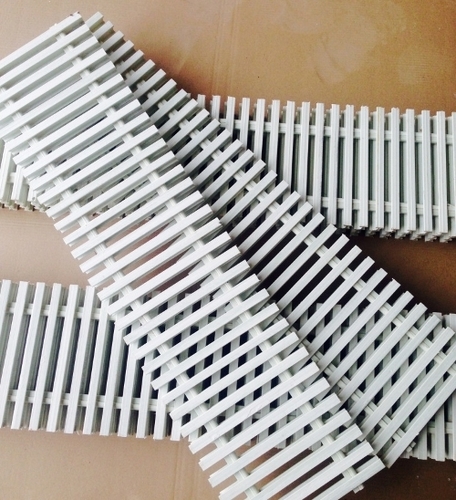

FRP

Cable Tray comes in a variety of sizes and configurations, such as a ladder,

perforated, and solid trays. To meet specific project requirements, it can be

custom-designed and manufactured. Because of its corrosion resistance,

durability, and ease of installation, it is an excellent alternative to

traditional metal cable trays.

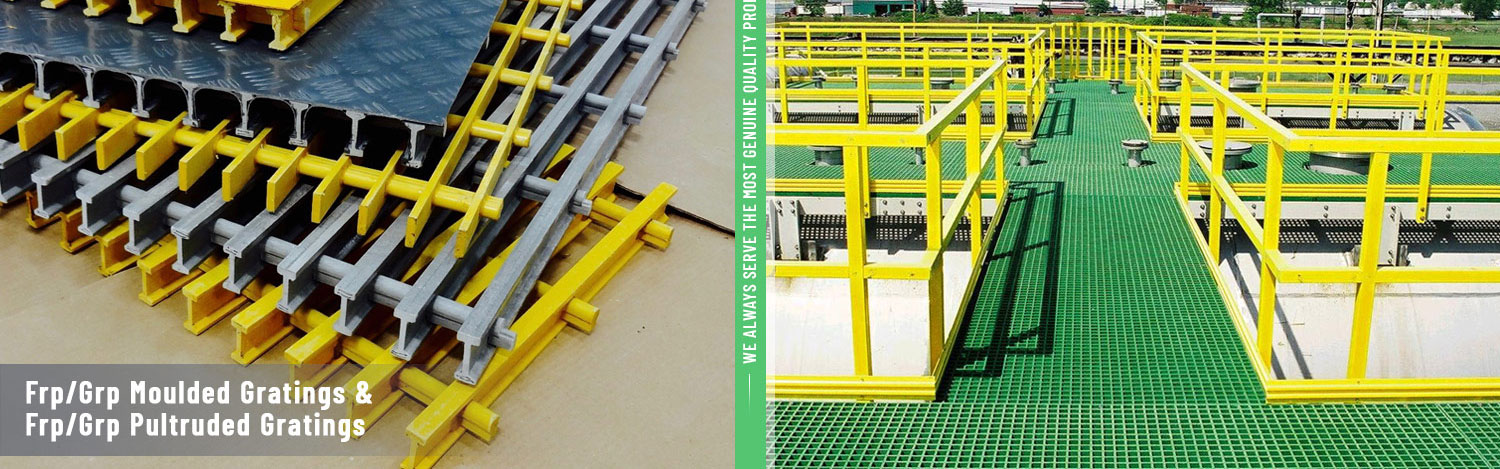

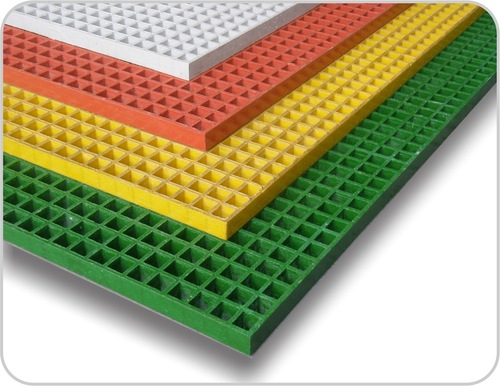

FRP

Gratings are commonly used in chemical plants, wastewater treatment plants, and

offshore platforms where they are subjected to corrosive and harsh environments.

Because of their corrosion resistance, durability, and ease of installation,

they are an excellent alternative to traditional metal gratings. They require

very low maintenance costs.

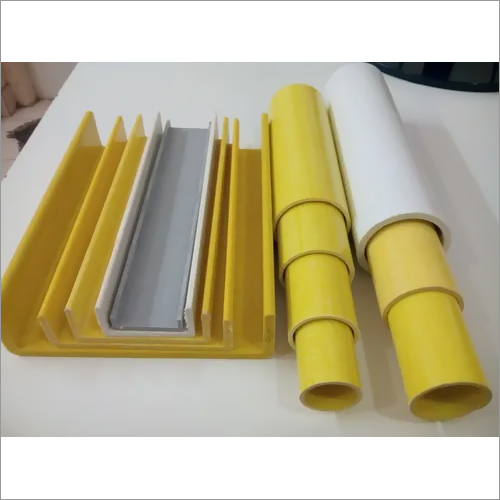

FRP

Pultruded Sections can be custom-designed and manufactured. They come in a

variety of shapes and configurations, such as beams, channels, angles, tubes,

and profiles. They are widely used in infrastructure applications like bridges

and tunnels, as well as in energy applications like wind turbine blades and

transmission line structures.

1st FLOOR, GANDHI CHAMBERS,

GONDAL ROAD,

RAJKOT - 360 002 (GUJARAT) INDIA.