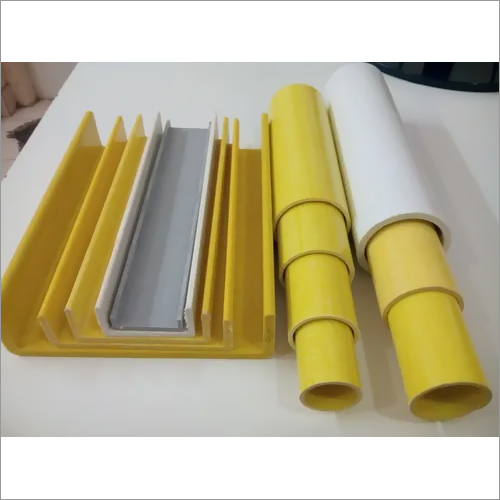

FR Pultruded Sections

160 INR

Product Details:

- Material Polyester Resin Vinylester Resin Epoxy Resin

- Application Bus bar support Dry type transformer spacers 11kv / 33kv cross armspower and distribution transformers D.O fuse Telescopic rods Earthing Discharge rods Garden toolsSporting goods

- Dimension (L*W*H) customised As Per user requirement Millimeter (mm)

- Click to view more

X

FR Pultruded Sections Price And Quantity

- 160 INR

- 100 meter Meter

- 160.00 - 180.00 INR

FR Pultruded Sections Product Specifications

- Bus bar support Dry type transformer spacers 11kv / 33kv cross armspower and distribution transformers D.O fuse Telescopic rods Earthing Discharge rods Garden toolsSporting goods

- Polyester Resin Vinylester Resin Epoxy Resin

- customised As Per user requirement Millimeter (mm)

FR Pultruded Sections Trade Information

- Mundra (Kutch)

- 1000 Meter Per Day

- 3 - 4 Week

- All India

Product Description

FRP Pultruded Sections

With our rich industry knowledge and experience, we are able to offer frp pultruded sections that is used in various construction works. It is designed using the finest quality FRP material and modern techniques under the supervision of seasoned professionals. To ensure its flawlessness, the offered product is tested on various parameters by our quality controllers. Offered frp pultruded sections is highly demanded in the market and is available at industry leading prices.

Features:

- Durability

- Optimum strength

- Smooth finish

- Robustness

Application:

- Bus bar support

- Dry type transformer spacers

- 11KV/33KV cross arms

- Other electrical insulation requirements

Available In:

- Polyester

- Vinyl ester

- Epoxy resins

Product details

|

Color |

Yellow |

|

Length |

5-10 m |

|

Finishing Type |

Powder Coated |

|

Material |

FRP |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

MAILING ADDRESS :

1st FLOOR, GANDHI CHAMBERS,

GONDAL ROAD,

RAJKOT - 360 002 (GUJARAT) INDIA.

1st FLOOR, GANDHI CHAMBERS,

GONDAL ROAD,

RAJKOT - 360 002 (GUJARAT) INDIA.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese